This evening I experimented some more with large acrylic relief plates on the large press. On my previous attempt, I found that my rubber Whelan Press blanket was so flexible that it was impossible to get sufficient pressure for good ink transfer without embossing the paper to the point where it wrinkled. For that initial attempt, the press had been loaded with

- Rubber Whelan Press blanket

- Newsprint to keep the blanket clean

- Masa print paper

- Relief plate

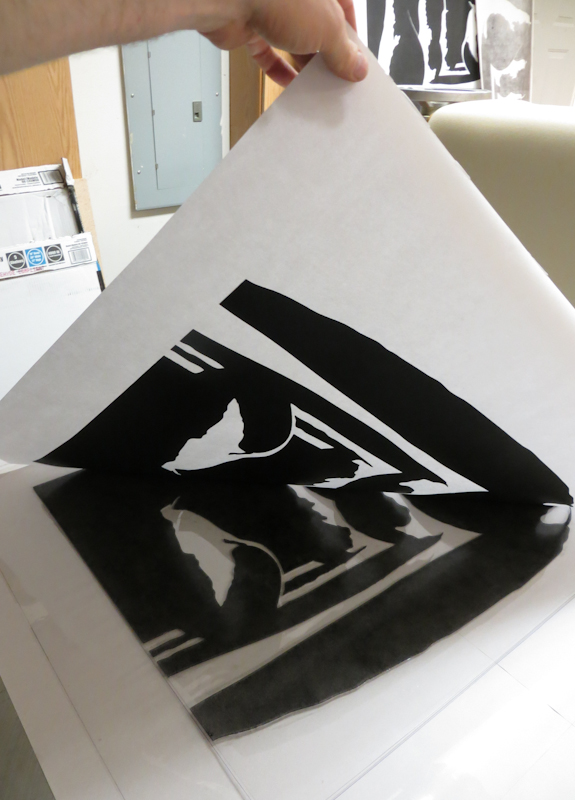

The next two photos show the poor ink transfer and wrinkling.

In this close up view of the first attempt you can see that the paper is wrinkling, even though there isn’t enough pressure for good ink transfer.

Tonight I rectified the problem by increasing the pressure after inserting a piece of 14-ply chipboard between the blanket and the newsprint. The chipboard, which is fairly stiff, was inserted to prevent the flexible rubber blanket from pressing the paper too deeply into the recesses in the plate. My new stack was

- Rubber Whelan Press blanket

- 14-ply chipboard

- Newsprint to keep the chipboard clean

- Masa print paper

- Relief plate

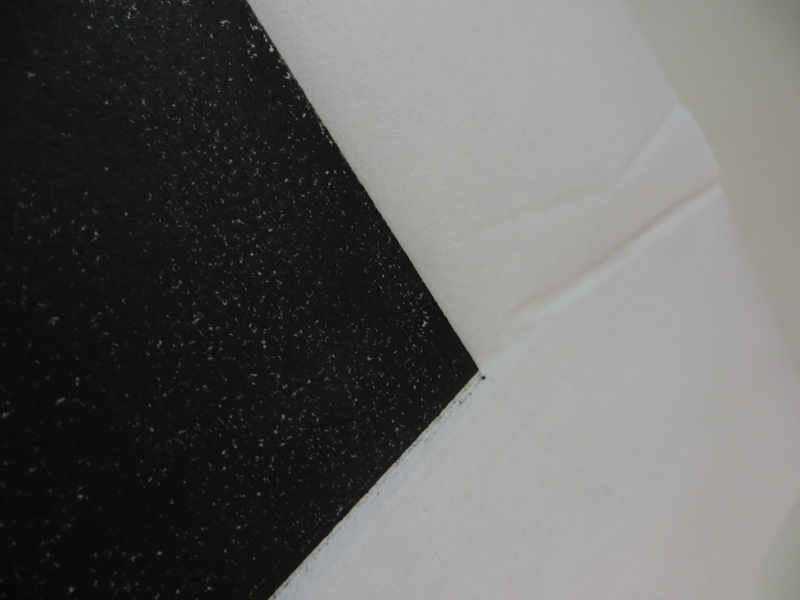

The result was a print with perfect ink transfer and just the right amount of embossing as you can see in the next two pictures.